Screening bagged flour to improve your quality

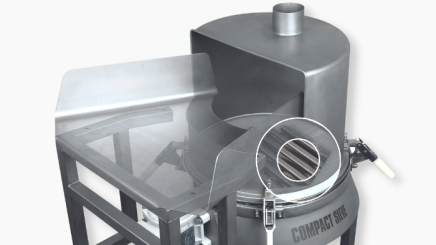

We have extensive knowledge of flour screening whether hard or soft wheat, semolina, corn flour or others. Whether you are a small artisan bakery or a large industrial flour mill, the Russell Compact Sieve® will remove contamination and lumps from your flour. This unique screener also provides increased productivity, reduced maintenance costs and improved operator safety.

When combined with our Vibrasonic® mesh deblinding system it allows you to sieve on finer screens and further improve your product quality.