Stokes replace equipment with a Self-Cleaning Russell Eco Filter

R.J. Stokes manufactures specialized paints which have to be filtered to a high quality using very fine screens. For many years Russell high speed open top vibratory sieves have been successfully used but in order to meet today’s health and safety legislation R.J. Stokes introduced non Russell enclosed disc style filters. Unfortunately, due to problems with the quality of the filtration from these machines and the mechanical unreliability with the design, a different solution was needed.

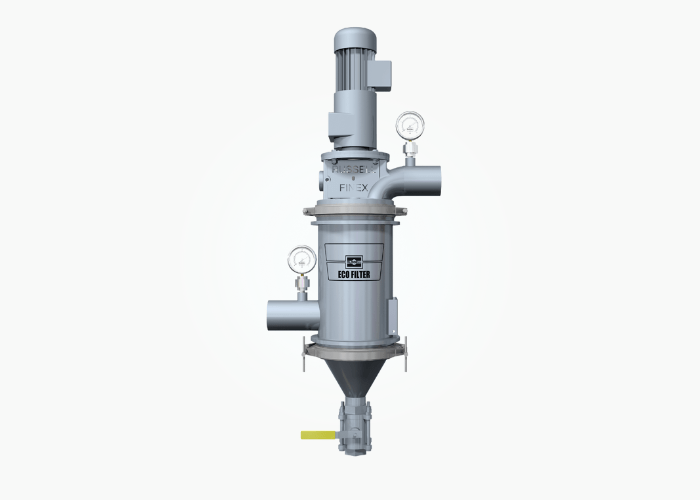

Russell Finex were able to offer that solution with the Self-Cleaning Russell Eco Filter®. The constant cleaning action of the SpiroKlene™ wipers on the stainless steel filter element means no more blockages and a constant flow of paint through the production process. The entire inner surface of the screen is continuously wiped by means of this unique spiral assembly. This positively drives oversize away from the filtration area, maintains consistent flow rates and keeps differential screen pressure low. Because the filter element lasts much longer than in conventional filters, parts are replaced less frequently, reducing downtime and producing further cost savings.

Russell Finex has a history of supplying separation equipment for a wide range of companies within the coatings industry. To find out more information about this application, and how it can be incorporated in your processing lines, please contact us.