The industrial filtration system screens liquid paint before packaging to remove contamination

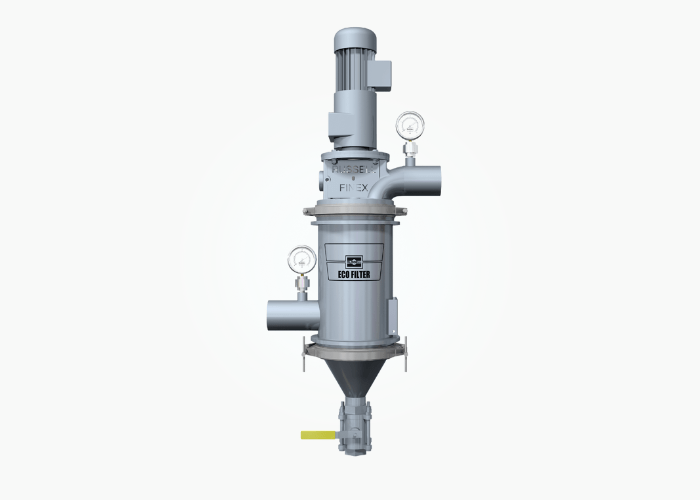

During the production of liquid paint it is essential to ensure there is no risk of contamination entering the product, whether it is airborne particles, unmixed product, or skins which have formed. To ensure the quality of the final product, such contamination needs to be removed. Installed after the mixing vessel prior to the packaging station, this demonstration video shows the Self-Cleaning Russell Eco Filter® successfully removing contamination from the liquid paint. Unlike conventional bag or basket filters, this filter uses a reusable stainless steel element and incorporates the unique SpiroKlene™ self-cleaning wiper system maximizing productivity and reducing costs and product wastage.

Russell Finex has a history of supplying self cleaning filters for a wide range of companies within the liquid paint industry. To find out more information about this application, and how it can be incorporated in your processing lines, please contact us.