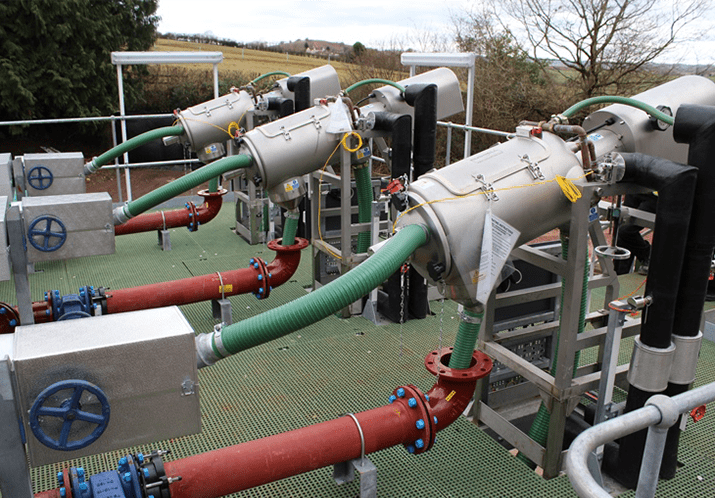

Centrifugal separators

Continuously remove solids from your liquids

Our Russell Liquid Solid Separator™ is perfect for removing larger solids concentrations from liquid slurries. This centrifugal separator can process flow rates of up to 100,000 litres per hour at mesh sizes down to 20 microns.