Improve the life and hygiene of your cooking oil and safeguard the quality of your food products

Why is there an oil filtration process?

The filtration of oil is of vital importance to ensure the product being cooked remains at the highest quality. When frying these products the oil can become contaminated as food parts remain in the liquid.

As such, one of the most important aspects of using oil in a production line is the choice of filtration medium used to process it. Without decent filtration equipment in place, the contamination risk increases and the product quality rapidly decreases. This is because the quality of the oil can affect factors such as the taste of the food product.

What are the benefits of oil filtration?

There are many benefits to oil filtration in a food production line. It is designed to remove impurities and contamination that build up in the oil as the product is submerged, as well as improve the overall quality of the end product.

Depending on how the oil is filtered, there is also a reduced cost as the oil does not have to be changed as frequently. In addition, oil filtration will help to protect your downstream equipment, making sure that your process line runs as efficiently as possible.

How can I improve my oil filtration process?

Improving your production line’s oil filtration processes usually starts with having the right equipment. Using steel mesh screens instead of polymer bag or paper filters, is a better way to filter frying oil as there is less likelihood of oil being lost or needing to wait for it to cool down. Filter media such as bags also increase waste costs and cause productivity issues, as they need to be regularly changed, interrupting production and reducing efficiency.

Considering operator safety is also very important when looking to improve your oil filtration process. Having a filter which has an enclosed and self-cleaning design helps to limit operator exposure to liquid and removes the risk of heat related injuries.

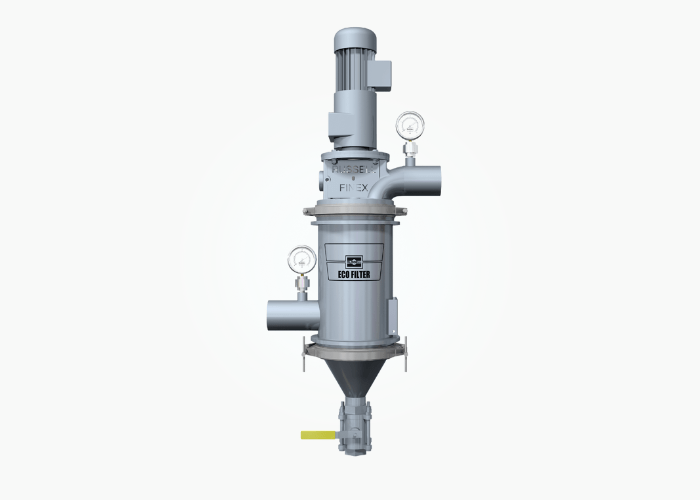

Russell Finex has an automated filtration solution to help businesses optimize their oil filtration processing lines with the Self-Cleaning Russell Eco Filter®. Capable of filtering high-temperature liquids, this unit’s self-cleaning design is ideal as there is no need to stop and change filter media. This unit is also able to filter at a finer particle size – as low as 15 microns – in one continuous operation which allows businesses to achieve an even cleaner and more consistent quality within their oil. Moreover, with a unique SpiroKlene™ wiper system, the Self-Cleaning Russell Eco Filter® provides continuous removal of contamination.

To find out more about how this self-cleaning filter, with a range of high-flow, sanitary, and high-temperature designs, can benefit your business, contact an experienced Russell Finex sales engineer today.

About Russell Finex

Founded in 1934, Russell Finex has over 85 years of experience providing businesses with a range of industrial sieving, separation, and filtration solutions. From oil filtration in the food and beverage industry, to ceramics, coatings, recycling, and water processing, we offer a range of machines to meet your production requirements.