Stay compliant whilst maintaining efficient health & safety regulations

Key concerns:

- What are the common risks?

- How can you improve operator safety?

- ATEX, DSEAR and OEL regulations

- HACCP and CCP

- The use of PPE

Health and safety in industrial manufacturing is highly important to protect the working conditions and overall health of operators and staff in the workplace, especially on the factory floor and other places of high risk.

According to the Health and Safety Executive (HSE) in the UK, over the last five years of statistics recorded on average around 4,100 injuries resulted in a worker’s absence of seven days or more. A further 33,000 workers suffered from an illness caused by their job in manufacturing – usually from a failure in health and safety protocols.

Common risks to be aware of:

- Mechanical failures (e.g. from machinery or the factory)

- Lack of knowledge which leads to increased human errors

- Explosive or hazardous chemicals

- Machines that contain moving parts

- Fire (e.g. handling flammable materials)

- Occupational health risks (e.g. working at height, noise)

Many of these risks can be mitigated through simple safeguarding measures and regulations. However, it is important to identify these risks, in order to effectively combat them.

How do you improve operator safety?

1. Provide product training and the right equipment

One key-way to improve operator safety is by providing employees with adequate product training. As a lack of knowledge is a key risk and can cause accidents, educating operators is a crucial countermeasure. Through this training, operators and staff can learn the best way to operate and utilize the product (e.g. heavy machinery), reducing the likelihood of accidents and alerting them to potential risks.

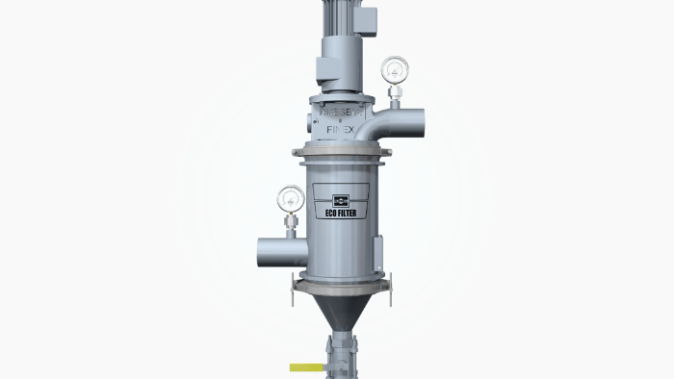

Making sure that the right equipment (such as an industrial sieve or filter in your business’ processing line) is selected for the correct application is also another way to improve operator health and safety. For example, utilizing a completely enclosed sieve or screener within a pneumatic conveying system for pharmaceutical powders helps to reduce the risk of hazardous chemical exposure. Or, when processing hot liquids such as oil, using a full enclosed filtration system – such as the Self-Cleaning Russell Eco Filter® – lowers the risk to operators as the liquid is wholly contained within the processing line.

2. Assess your workplace risks

Assessing your workplace occupational safety via a safety and risk assessment is also another important way to improve operator safety. This is the best practice to use to ensure business leaders are given a picture of how to improve and safeguard their workforce against potential risks. Risk assessment practice should look at and deal with the following questions:

- What are the potential risks of routine operations?

- Considering the potential hazards, how many employees could this affect?

- Is there data that can help manufacturers judge the likelihood of industrial accidents?

What regulations are there?

EU regulations are continually changing, but there are some main ones that should be adhered to when assessing health and safety in the workplace. Making certain that machines are compliant with industry standards, which will differ depending on the industry or application, is important to ensure any risk to the end product is limited.

ATEX, DSEAR, and OEL

Machines that process hazardous chemicals or exist in a potentially explosive atmosphere need to be compliant to the appropriate standards and directives such as DSEAR and ATEX when operating within the EU. This means that the machinery and its operators need to be able to eliminate or control the risks gained from working in or with a potentially explosive environment. This is a high priority in industries such as the pharmaceutical industry, where the processing of potentially explosive and hazardous powders is a common occurrence.

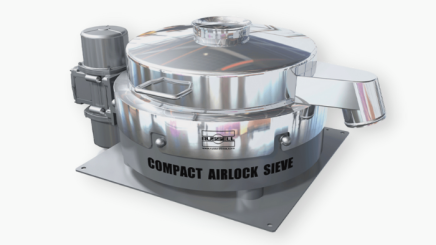

Potential exposure risks to harmful powders also need to be considered when assessing operator safety. This is a risk that is monitored by the occupational exposure limit (OEL), a limit which establishes the safe levels of exposure limits on a variety of different materials. Machinery that processes such powders should be assessed using this, in order to minimize risk to operator health. The Russell Compact Airlock Sieve™ is specifically designed with a patented TLI (Twist, Lock and Inflate) pneumatic clamping system, providing validated OEL 5 containment and reducing dust and powders potentially released into the surrounding atmosphere.

Russell Finex provide businesses with comprehensive documentation to ensure validation processes are kept to a minimum. All equipment from Russell Finex is manufactured to the highest of standards, as well as providing certification for machines that extensively operate in hazardous environments (such as ATEX or IECEX).

Critical Control Points (CCP) and HACCP

In the food and beverage industry, there are other regulations to consider to make sure the risk of contamination is minimized and operator safety is upheld. Due to the nature of the products that are handled – such as milk powder, flour, or chocolate - there have been increasingly strict Manual Handling Operations regulations which means that machines must comply in order to mitigate operator risk, whilst still handling high throughput of product. Systems like HACCP are utilized to identify and mitigate hazards and critical control points, done to protect products and operators. This means that if there is a fault or risk in any machinery that processes food, or risks the health of operators, this system will monitor and take corrective action.

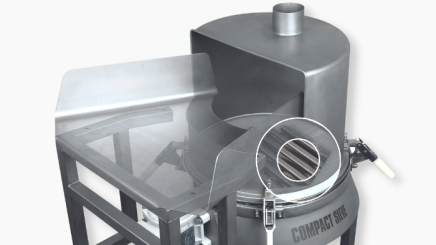

Examples of such corrective actions include placing a sieving unit into a processing line to prevent any risk of contamination. The Russell Compact 3in1 Sieve™ is an example of this sieving unit, designed specifically to meet HACCP requirements within the food industry when ingredients such as flour or sugar are debagged into a food processing line.

The use of PPE

How can Russell Finex help?

With 85 years' experience, Russell Finex has the longevity and knowledge to ensure that operator health and safety is protected. With a range of innovative sieves, separators, and filters, each unit can be adapted and designed specifically to meet your industry’s requirements - from food and beverage to pharmaceutical - to mitigate any risk and comply with a variety of health and safety standards.

To find out more about how we can help your business comply with health and safety regulations, contact us today.