Automatic self-cleaning filter machine provides smart solution as food producer replaces paper filtration method with cooking oil filtration system

Milhans Gida ve Tarim Urunleri (Milhans) is a leading producer of high-quality nut products, and a major manufacturer of private-label products to some of Turkey’s largest food retailers, as well as supplying its own range of snacks.

A key area of production is the peanut processing line, where it is imperative that the quality and hygiene of the final products are of the highest quality. As Milhans continues to meet increasing demand for its products, the equipment used throughout the plant must meet high capacity levels without compromising product quality. When seeking a cooking oil filtration system to optimize the recovery of frying oil from the fryer, Milhans consulted Russell Finex, specialists in separation equipment for the food industry.

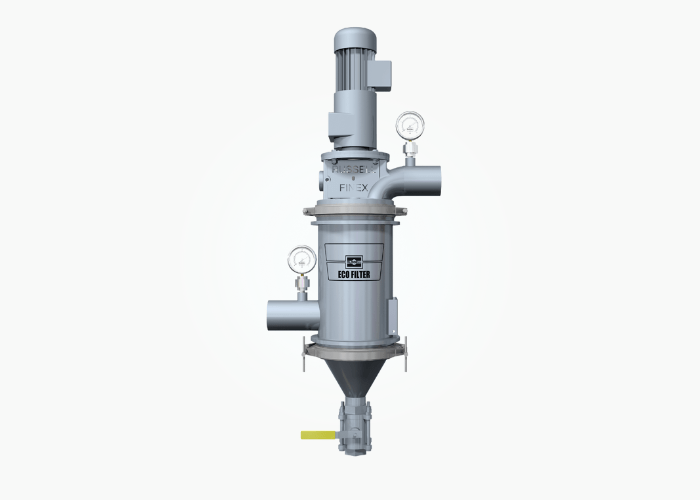

The Self-Cleaning Russell Eco Filter® with a Russell Filter Management System™ was the solution for recovering the used frying oil. This inline filter machine for cooking oils was easy to install in the existing production line, capable of filtering high-temperature liquids and providing a significant upgrade on the previous paper cartridge filters.

As well as delivering increased throughput, the new frying oil filter ensures an even finer, consistent quality of cooking oil. In addition, the unique self-cleaning design means there are no stoppages to change filter cartridges and no slowing of throughput to clean blocked filter elements. The filters are totally enclosed, meaning no fumes and limited operator exposure to liquid. A range of high-flow, high-temperature and sanitary liquid filters is available to suit various applications. The addition of the Russell Filter Management System™ allows complete automation of the Self-Cleaning Russell Eco Filter®. The automatic filtration system continuously monitors the filtration process, enabling the filter to run efficiently without operator involvement.

Contact Russell Finex to discover how a range of innovative self-cleaning filters can improve the efficiency of your food production line.

What our clients say

“Our new filter from Russell Finex has significantly improved this area of production. We can expect to achieve a return on investment within eight months through savings made on not having to purchase replacement paper filter cartridges.”