Screening metal AM powders

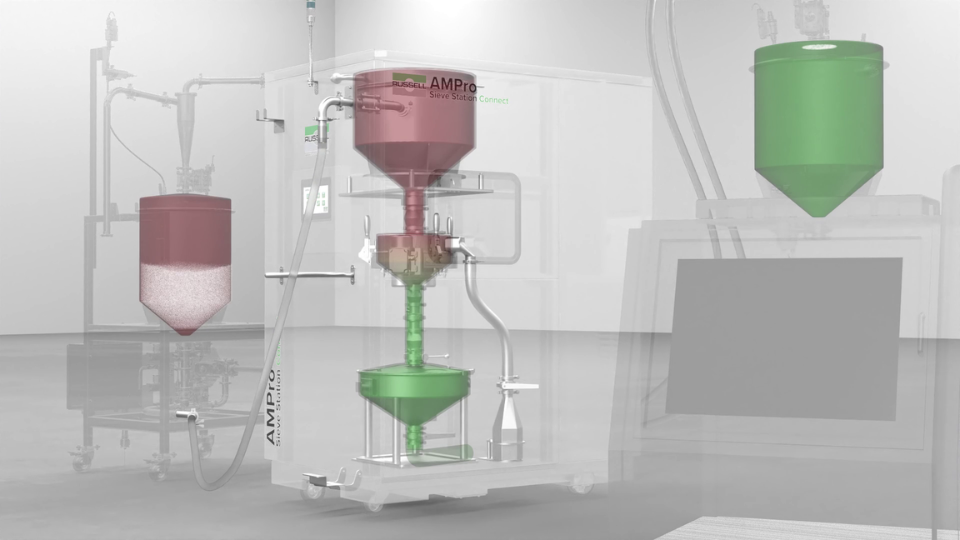

Fully-automated and contained metal powder screening system for additive manufacturers qualifies titanium powder for use in 3D printing.

Read moreThe AMPro® Sieve Station Connect offers versatility and automation to future-proof your powder handling strategy. It is designed to provide optimum sieving efficiency, ensuring your powder is ready for use or reuse whenever you require it.

New plug-and-play functionality enables you to easily expand your printer fleet or increase powder consumption with additional peripherals. Cloud monitoring allows remote access to information and support.

Russell Compact Sieve® style technology for tool-free, easy cleaning of minimal contact parts

Remove all out of spec powder, recovering all usable powder quickly

Can be connected now or in the future to multiple peripherals like printers, bulk storage tanks, de-powdering stations and delivery hoppers

Fully automated and enclosed system minimizing operator exposure

Redesigned from the ground up, the new AMPro® Sieve Station Connect, offers top-tier system monitoring and control, enhanced ergonomics, maintenance efficiency and performance.

The new ‘connect’ design has two key components:

Plug-and-play functionality, enabling adaptable system configuration enabling you to expand your printer fleet or increase powder consumption with ease.

Advanced connectivity, enabling remote optimization and monitoring. Connect to plant communication protocols like OPC-UA and data logging to optimize your powder usage remotely and achieve end-to-end powder traceability.

With an integrated storage hopper and convey system, this all-in-one powder management system includes Smart Flow™ technology for autonomous sieving as well as data logging capabilities for process validation. This also includes options for connecting directly to your 3D printer for a fully closed-loop powder handling system.

The AMPro® Sieve Station Connect also offers:

“The Russell AMPro Sieve Station is incredibly intuitive to use, conveying and sieving into a compact unit. The reliability and repeatability offered by this machine made it the best solution for us, improving powder traceability and quality, and future proofed long term collaboration between Russell Finex and the MTC for years to come.”

Vince Sparrow • MTC

Fully-automated and contained metal powder screening system for additive manufacturers qualifies titanium powder for use in 3D printing.

Read more