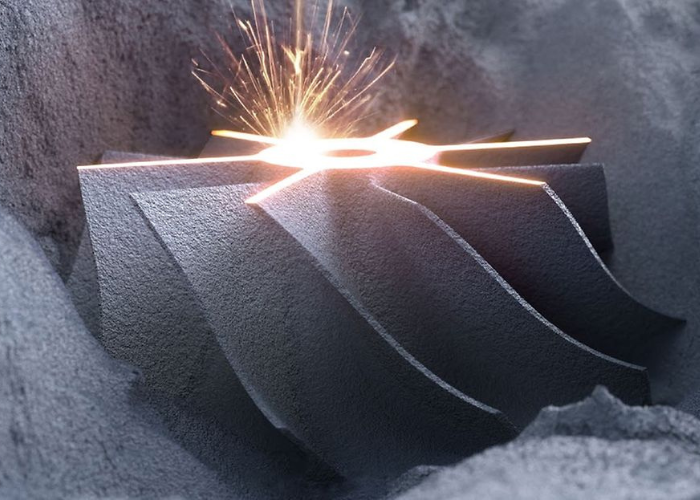

Recycling additive manufacturing powder

Powder handling and qualification is essential for additive manufacturers to maintain productivity and profitability.

Working with the additive manufacturing (AM) industry since inception, we’ve developed our award-winning range of powder handling systems. Whether it’s check screening virgin powder, reclaiming and recycling powder or grading powder, we’ve got the range of solutions for any stage or scale your processing requires.

Read more below about some common AM applications and how our solutions can help you.