Finex Separator improves your quality and productivity

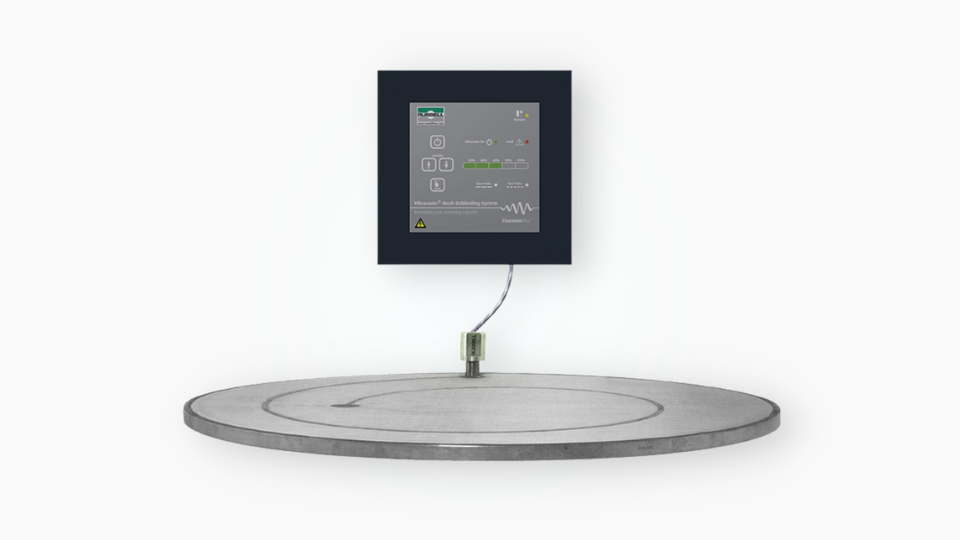

Powerful vibratory separator accurately grades particle size fractions

The Finex Separator™ is the ultimate solution for quickly and accurately grading or sizing powders. It can also separate heavy or sticky solids from liquids where traditional separators fail.

Using multiple screens, you can sort up to five differently-sized fractions. The innovative vibratory drive system and rubber suspension increases productivity by up to 70% compared to conventional separators. Maintenance and noise are also reduced significantly, protecting your operators.

Suitable across a range of industries, including pharmaceuticals, chemicals and food and beverage.