Protect your product quality with our compact vibratory sieve

High-capacity screener improves your productivity

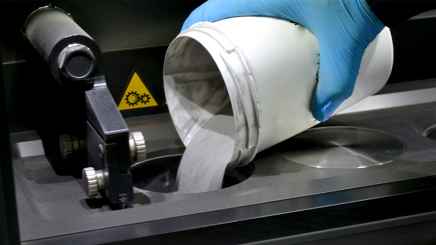

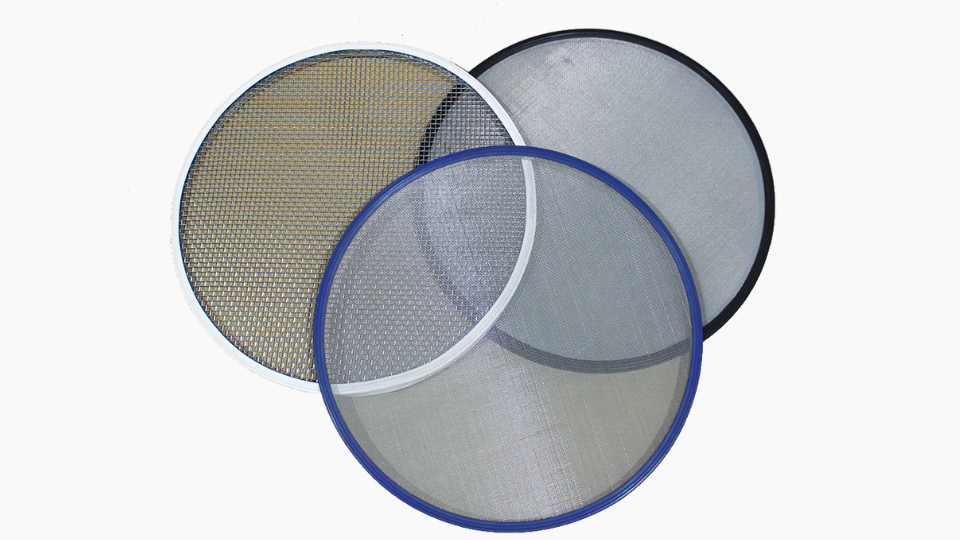

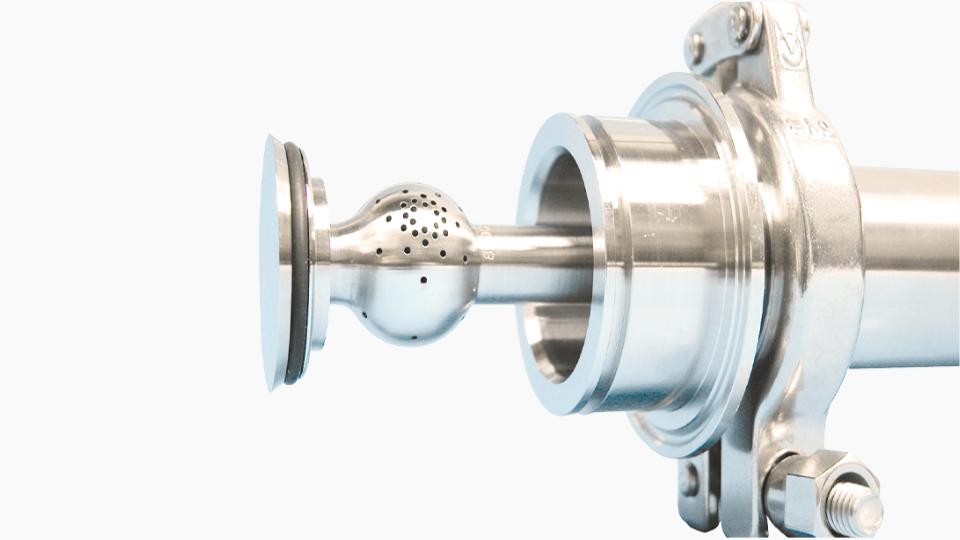

The Russell Compact Sieve® quickly removes contamination from powders and liquid slurries. It is extremely quiet and doesn’t need any tools to disassemble. All the contact parts are easy to clean so change overs are quick and improve your productivity.

Using only half the space of a traditional vibratory sieve, the Russell Compact Sieve® is ideal for fitting into existing production lines.

Used in a range of applications, including sieving pharmaceutical powders, various food powders and powder paint, these industrial screeners come in different sizes and options to match your sieving requirements. Compared to a standard vibratory sieve of the same diameter, the Russell Compact Sieve® achieves much higher capacities.