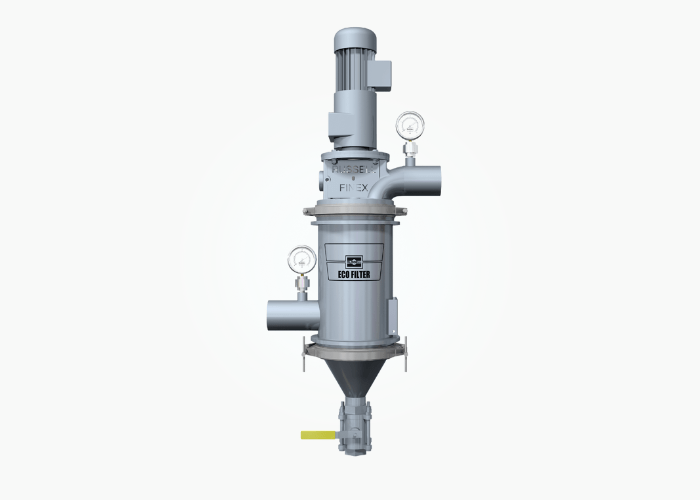

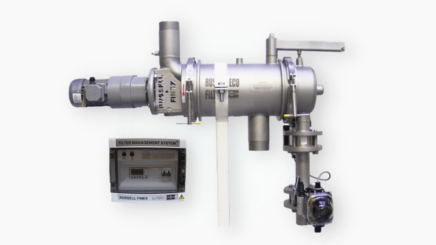

Self-cleaning filters

Continuous removal of contamination from liquids

Our Self-Cleaning Russell Eco Filter® range improves your liquid quality and keeps your operators safe from product exposure. They offer many advantages over screeners, bag or cartridge systems.

Our units will increase your productivity, protect your environment and minimize maintenance costs. We offer a range of options and can customize our products to suit your application and installation perfectly.