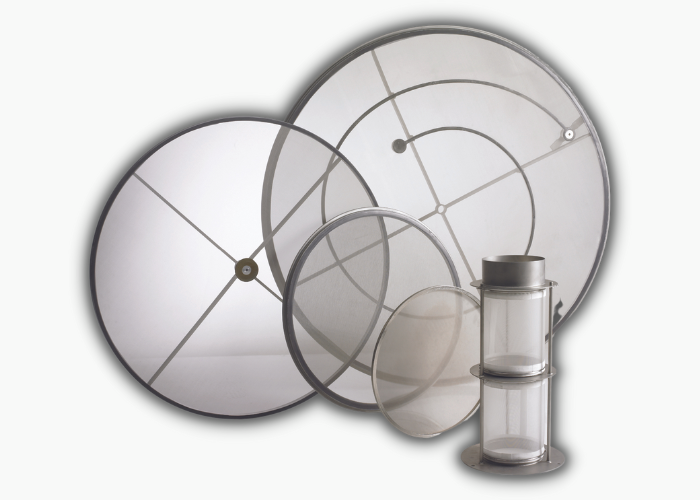

Sieve re-screening

High-quality mesh screen replacement

Mesh screens are critical to your product quality and productivity. We offer high quality re-meshing services to reduce your costs and environmental impact.

Cost-effective care

Instead of replacing the entire mesh screen, re-meshing is a cost-effective solution for mesh damage or low tension mesh. We offer fast, high-quality re-meshing to ensure your equipment is maintained to the highest standard.

If you need multiple screens re-meshed or you are located far from our facilities, our bulk re-meshing service may be more suitable. We can also offer customized stocking policies so meshes and frames are always available.

Simply complete the returns slip, send your screen to us, and our team will do the rest.