Check screeners improve your product quality

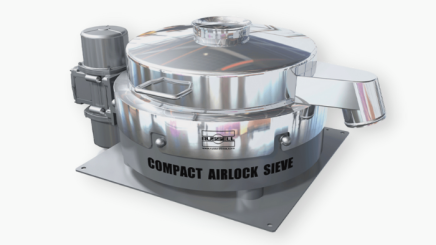

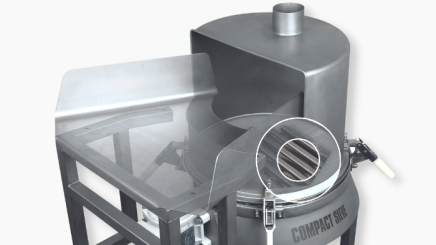

Industrial check screening equipment, also known as safety screeners or quality control sieves, protect the quality of your powder or liquid products by removing oversize contamination.

Our units are designed to increase your productivity, protect your operators and minimize maintenance costs. They are also very small and can be fitted into existing production lines.

We offer a range of options to suit your screening requirements and can customize our products to suit your application and installation perfectly.