Screening to improve your excipient quality

A vibratory sieve or screener is an essential part of every pharmaceutical production process. A product recall because of a quality defect or safety issue can damage the reputation of any manufacturer.

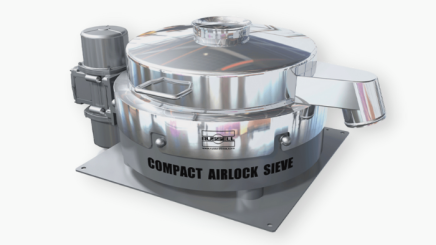

Excipients such as lactose, starch and Microcrystalline Cellulose (MCC) are regularly used in oral solid dosage formulations such as tablets, capsules or sachets. We will help you remove these issues with our Russell Compact Sieve® which increases your productivity, improves screening accuracy and operator safety.

When combined with our Vibrasonic® mesh deblinding system it also allows you to sieve on finer screens and further improve your product quality.