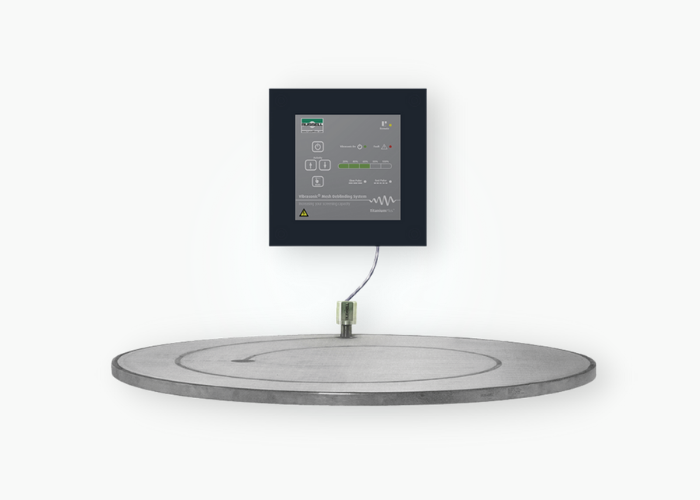

600mm Russell Compact Sieve® with Russell Vibrasonic® Deblinding System

Whether micronizing, milling or utilizing powder coatings for overspray powder, it is highly important that these coatings remain free of contamination. Oversize particles such as lumps of powder, or foreign bodies, allow for blockages in spray-gun applicators, which can lead to increased production downtime and increased waste.

In this demonstration video, the powder coatings are emptied into the check screener from an FIBC. The product is then sieved through the fine mesh in order to remove any oversized contamination from the product, to refine and improve its quality. The Russell Vibrasonic® Deblinding System, which is attached to the mesh, prevents blinding and improve the throughput rate of the product.

Ideal for improved sieving efficiency, this high capacity vibratory industrial screener can provide optimum sieving capacity without sacrificing product purity. As its name suggests, the Russell Compact Sieve® is designed to allow for it to fit easily into production lines, and its enclosed screening allows for complete product containment, ideal for hazardous products, and chemicals like powder coatings.

With over 85 years’ experience in the manufacturing industry, Russell Finex has used its expertise and knowledge to develop the Russell Compact Sieve®, alongside its wide range of other sieving and separation equipment. Please contact us for more information about this application or how we can help with your specific requirements.