Russell Finex provides New Balance with an innovative AM powder sieving solution, increasing its throughput and ensuring powder purity

Established in 1906, New Balance Athletics, Inc., informally known simply as New Balance, is one of the world’s largest athletic shoe manufacturers. One of New Balance’s latest innovations is the addition of an additive manufacturing laboratory; along with the production of the world’s first laser printed shoe. The Zante Generate is the world’s first running shoe with a 3D printed midsole. Composed of Duraform® TPU Elastomer, the revolutionary sneaker is made using a laser sintering process; which converts this additive manufacturing powder into solid cross sections using a laser.

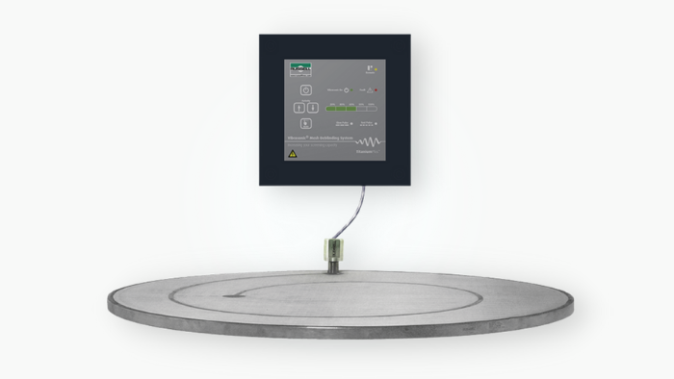

Following consultations and a product trial at Russell Finex’s specialized test facility, New Balance purchased a Russell Compact Sieve® and Vibrasonic® Deblinding System. This combination not only fulfills the athletic giant’s need to increase throughput, but also ensures purity of the processed 3D printing powders. The Russell Compact Sieve® is a versatile, high-capacity industrial screener that is half the height of a traditional sieve. Equipped with a solid rubber suspension, the revolutionary sieve allows for quieter operation - as low as 70dBA. Designed to minimize cleaning time, the unit is easy to strip down without the need for tools; allowing operators to easily access mesh screens.

The inventors of ultrasonic sieve deblinding technology, Russell Finex’s patented Vibrasonic® Deblinding System ensures difficult and fragile powders are quickly processed. In addition, the system ensures equipment is kept running at its optimum performance, upholds throughput rates, maximizes the life of mesh screens, and minimizes the loss of good product.

Russell Finex manufactures a wide range of innovative solutions for sieving additive manufacturing powders. Contact us for more information.

What our clients say

“To put in numerical terms, to sieve 20kg of material using the OEM provided equipment would take approximately eight hours. With the [Russell Finex] sieve plus Vibrasonic, I can do the same amount in roughly ten minutes.”