High efficiency filtration system removes foreign contamination to safeguard the end product

Acrylic resin is a product that is widely used in a variety of different industrial processes, in wall paints, or in the automotive industry. When processing resins, it is highly important that the final product meets quality and consistency standards. A key stage of the resin process line is filtration, ensuring that agglomerates and foreign bodies are removed, prior to filling the liquid into an IBC or drum where it will then be stored prior to transportation.

In this demonstration video, acrylic resin is filtered using a self-cleaning industrial filter. As resin is a thick liquid, the inline filter allows for an increased throughput rate versus other methods, such as traditional static basket strainers, which regularly block up and require frequent maintenance to clean filter elements. The contamination is removed, allowing the liquid to be processed and stored in drums.

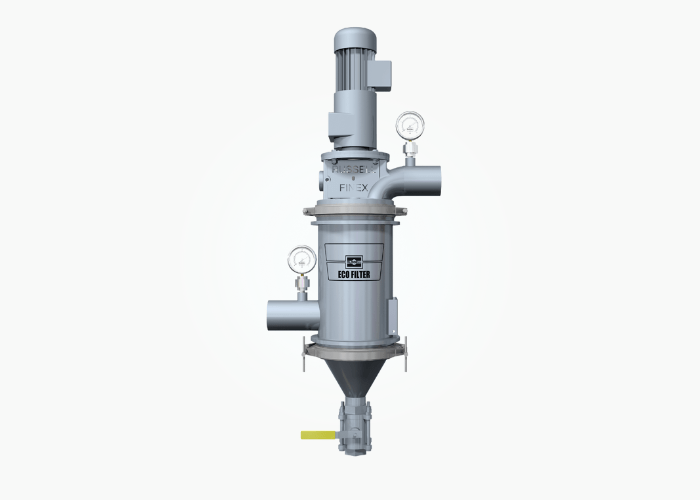

The Self-Cleaning Russell Eco Filter® is a high-performance, efficient solution for ensuring the quality of liquids and protecting them from contamination. The filters are enclosed, in order to protect operators’ health and safety, and with an inbuilt SpiroKlene™ wiper system this solution allows for continuous and efficient filtration down to 10 microns.

A global leader in industrial separation technology for 85 years, Russell Finex has been supplying the a variety of filtration solutions for coating industry. To find out how a range of different solutions could benefit your business, contact Russell Finex today