The ultimate solution to all your deblinding problems

When sieving difficult powders, the safety and security of

Traditional but less effective methods to reduce blinding and blockage of the mesh exist, such as changing the mesh aperture to increase flow rate of product or installing mechanical deblinding discs (also known as “scrapers”), or rubber balls.

What makes Russell Finex's Vibrasonic® Deblinding system unique?

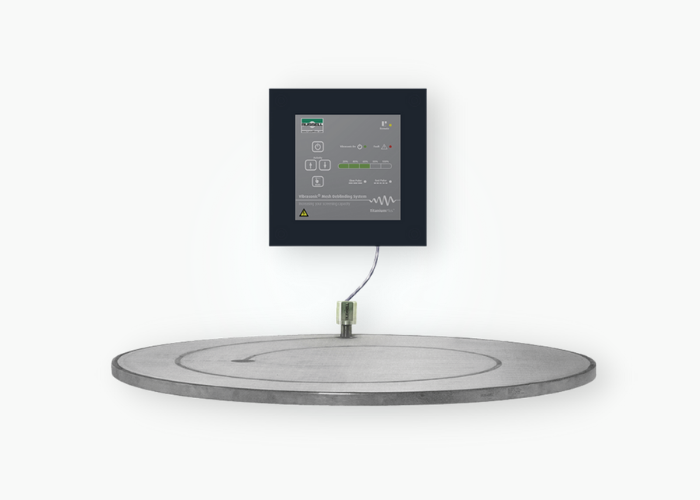

An innovative solution which effectively combats such issues, offered by Russell Finex for more than 20 years, is the patented Vibrasonic® Deblinding System (VDS). Unlike other businesses in the market, Russell Finex has the unique honor of not only being the originators of the VDS equipment, but also the only global manufacturing supplier to make and support ultrasonic and sieving systems.

This means that Russell Finex is equipped with both the technical know-how to ensure the complete sieving solution is designed fit for purpose, and that it can be supported throughout its life. This ensures that not only can the highest product quality be assured to businesses across the globe, but that ongoing support can be provided in-house. This is particularly important when maintaining sieve mesh screens as Russell Finex can provide meshing services all over the world.

How can the Vibrasonic® Deblinding system benefit you?

Russell Finex’s revolutionary deblinding system eliminates mesh blinding and blockages, increasing both productivity and longevity of the mesh screen itself. When the Vibrasonic® is activated, it allows the mesh screen to stay clean, providing operators with a reliable and consistent flow rate.

Suitable for a variety of different industries, from food and beverage, to coatings, ceramics, and pharmaceuticals, the Vibrasonic® Deblinding System can be retrofitted to any existing Russell Finex sieve, as well as non-Russell equipment.

The benefits of this ultrasonic technology, over other options like scrapers and rubber balls, are that there is a reduction in contamination caused by the deblinding technology, and there is less need for production to stop for mesh replacement as a result. Additionally, using this Vibrasonic technology, the overall product quality is improved as it allows product to be sieved on finer meshes (as low as 20 micron) in order to obtain a better-quality final product.

Some additional features on this ultrasonic range include ultrasonic probes and ultrasonic mesh screens. The generators are also specifically designed to be ATEX compliant, so this technology can be made available for even the most hazardous environments. These configurations showcase the flexibility of the Vibrasonic® range, ensuring that Russell Finex can meet the need of any application.

About Russell Finex

With over 85 years’ experience supplying sieving solutions to companies across the globe, Russell Finex is a world leader in a variety of different industries. The range of ultrasonic deblinding solutions, joined with the expertise in sieving equipment, prove that the company has the experience to meet, and sustain, any businesses requirements. Contact us today to find out more.