Improve your product quality with the cost-effective Finex Ultima™

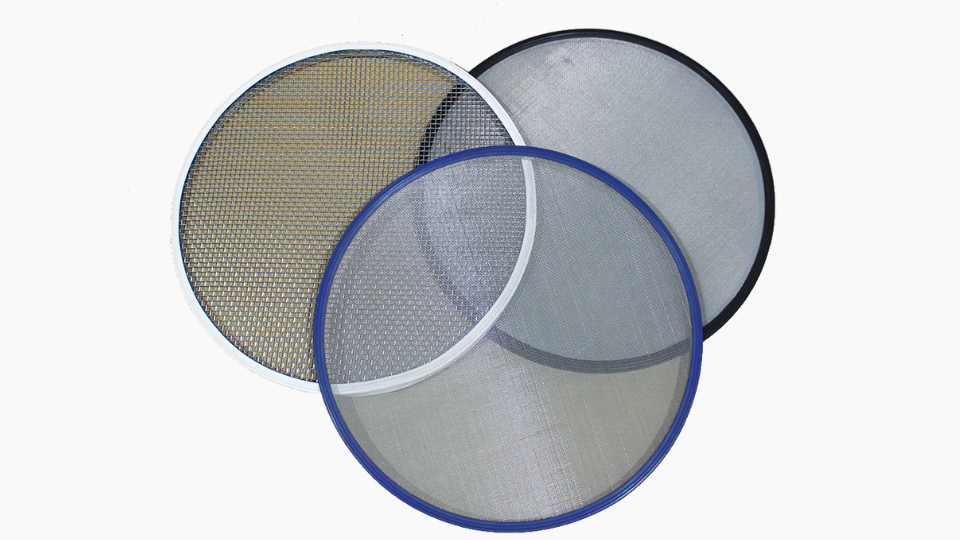

Accurate separation for wet or dry applications

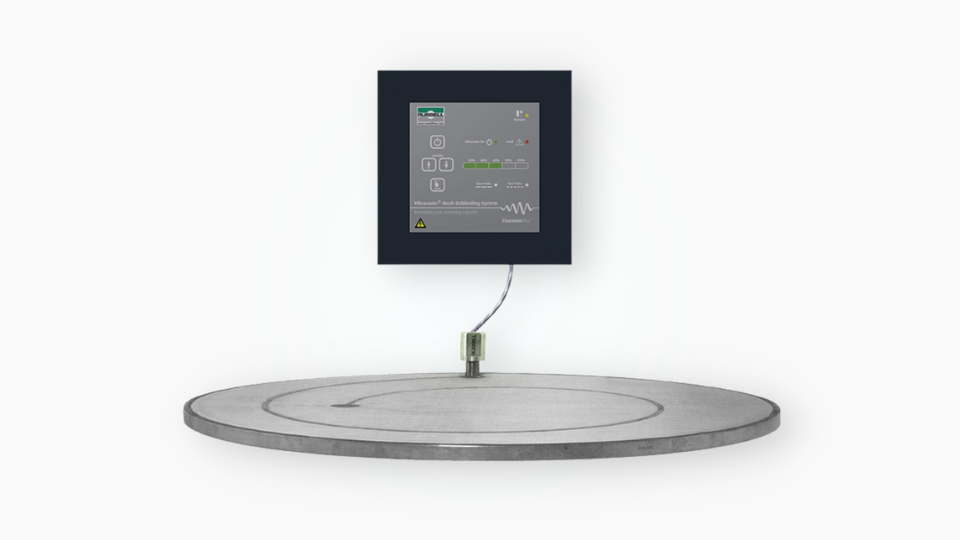

The Finex Ultima™ is a cost effective upgrade over spring mounted separators. It is suitable for a variety of wet and dry screening applications. The unique Russell Finex rubber suspension system gives increased productivity and lower noise levels than traditional models. Its hygienic, high-clean open frame design makes this fully stainless-steel unit ideal for the food and pharmaceutical industries and also many others.

To match the requirements of a diversity of applications and throughput rates, the Finex Ultima™ is available in four standard diameters from 30” (750mm), to 60” (1500mm) .