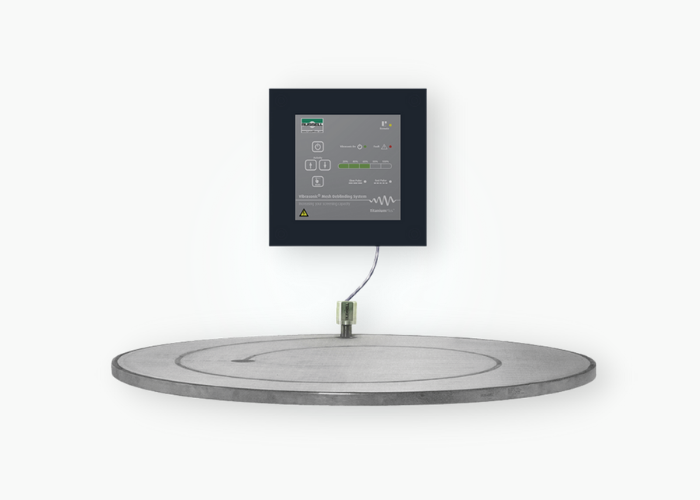

Russell Vibrasonic® Deblinding System

A wide range of sizes and designs available to suit your specific requirements.

Read moreThe Russell Vibrasonic® Deblinding System enables sieving on finer meshes (down to 20 microns) without any blocking or blinding of the apertures. This allows you to improve your final product quality and significantly increase your screening capacity.

It also increases the life of your mesh screens as they no longer need to be removed and cleaned mechanically by your operators. Our ultrasonic systems can be fitted to new and existing vibrating sieves and screeners.

Russell Finex invented the use of ultrasonics with sieves and is the only company to manufacture both sieving and ultrasonic equipment. This allows us to fully optimize their integration to give you the best solution.

A wide range of sizes and designs available to suit your specific requirements.

Read moreUltrasonic separation allows for easier separation of bulk powders such as metal powders, paints, chemicals or food powders. An ultrasonic frequency is passed through to the sieve mesh, causing it to vibrate. This prevents blinding, or blockage, thereby letting particles pass through the mesh more easily.

Materials such as metals and pharmaceutical powders can present a challenge in sieving as they easily stick to mesh apertures, causing build-up which can reduce throughput rates and product quality. An ultrasonic deblinding system provides a fully automated solution for mesh blinding to increase production rates while preventing mesh damage.

Ultrasonic deblinding sieves and separators utilize high-frequency vibrations generated by a transducer mounted directly onto the mesh screen. These vibrations create a bouncing effect on the sieve surface, preventing particles from sticking or lodging into the screen apertures. The ultrasonic energy breaks down the static charges and surface tension that often causes mesh blinding or blocking, allowing the material to pass through unhindered. This advanced technology ensures continuous screening, even for difficult-to-screen powders, fine particles, or materials prone to agglomeration.

Ultrasonic technology for sieve meshes improves product quality by enhancing accuracy, enabling finer sieving of powders and enhancing quality control. This, in turn, allows improved quality of final products or the ability to produce products that were previously not possible. This technology is widely used across industries like pharmaceuticals and powder coating, offering significant benefits such as improved product quality.

Yes, ultrasonic deblinding sieves and separators can be tailored to meet the unique needs of various industries. Russell Finex offers customization options such as choosing the appropriate screen material and other contact parts, mesh size, and overall design to suit specific applications. Whether it's food processing, pharmaceuticals, chemicals, or any other industry, ultrasonic sieves and separators can be optimized for different particle sizes, flow rates, and separation efficiencies. This flexibility ensures optimal performance and enables businesses to achieve precise and reliable screening results, regardless of industry requirements.

Ultrasonic deblinding sieves are highly effective in enhancing powder sieving efficiency. By utilizing high-frequency vibrations, these sieves prevent blinding and blockages that commonly occur during the sieving process. The ultrasonic energy dislodges particles, agglomerates, and other contaminants from the screen surface, ensuring a consistent flow of powder and reducing downtime. This leads to improved throughput, higher screening accuracy, and increased productivity, making ultrasonic deblinding sieves an indispensable tool for achieving optimal powder sieving efficiency. Statistic: Studies have shown that ultrasonic deblinding sieves can increase sieving efficiency by up to 300% when compared to traditional methods.

Absolutely. Ultrasonic deblinding sieves are designed to handle a wide range of powders, including fine particles, difficult-to-screen materials, and those prone to agglomeration. These sieves can be customized with various mesh sizes and screen materials to accommodate specific powder characteristics. Whether it's pharmaceutical powders, chemical compounds, food ingredients, or any other type of powder, ultrasonic deblinding sieves provide precise and reliable screening, ensuring optimal separation efficiency regardless of powder size or composition.