Discover how Russell Finex’s equipment can help to improve your food processing lines

Over the last year, the food industry has undergone a massive change. Boosted by the COVID-19 pandemic, despite the industry being affected by lockdown measures the rise in consumer demand for fast and affordable processed products has led to the need for companies to scale up their operations. [i] This has included automated machines and processes in its production lines, such as pneumatic conveying and bag dumping.

Russell Finex provides a variety of automation solutions for the food industry. From pneumatically assisted sieving, filter management systems, to bagged ingredients screening using a sack tipping platform, there is a solution for businesses looking to improve the efficiency of their production lines.

What are the benefits of automation in the food industry?

There are various benefits to automation, especially in the food industry. Automated machinery in food production lines makes the food sieving and packaging process easier for operators and improves the overall efficiency of the production line. It works as an effective solution, helping overcome problems in production lines to improve product yield and enhance productivity.

Operator health and safety is also protected. It minimizes the risk of accidents and limits the possibility of hazardous fumes being released into the workspace, whilst also freeing up operators for other value-added tasks and reducing production line downtime.

How can Russell Finex help with automated solutions?

Russell Finex has a range of solutions to help food manufacturers improve their processing lines and achieve increased product quality. Some specific automated solutions include:

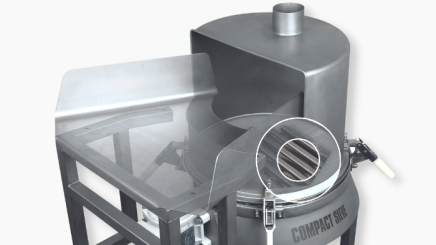

- The Russell Finex 3in1 Compact Sieve™is specifically designed to improve operator safety with its low-level bag emptying platform. The integrated dust hood on the tipping platform can be connected to a dust extraction system, protecting the health and safety of the operator.

- The Russell Filter Management System™ is another unit that allows for automation, removing operator involvement and continuously monitoring the filtration process. It monitors pressure differences to automatically clean the filter by ejecting contamination. This allows your filter to run efficiently and safely, protecting the operator, your environment, and filter from harm.

- The Russell Compact Self-Loading Sieve™ allows for ingredients to be vacuumed from a bag or bin conveyed to a point above a mixer or other piece of process equipment. The powder is then sieved before dropping into the next part of the process without any manual handling.

About Russell Finex

Founded in 1934, Russell Finex has over 85 years of experience providing the food and beverage industry with a variety of different sieving and filtration solutions. Optimizing businesses processing lines and providing end-customers with higher product quality, Russell Finex strives for quality in all of its operations, and has served global food industry customers including Nestlé, Godiva, and Mondelēz.

Contact an experienced sales engineer for more information about how your food production line can be automated today.

[i] Links:

1. “Food Manufacturing Trends for 2021”: https://www.foodmanufacture.co.uk/Article/2021/01/04/Food-trends-for-2021