Finex 22" flexible sifter improves your product quality

Versatile screener removes contamination from the most difficult products

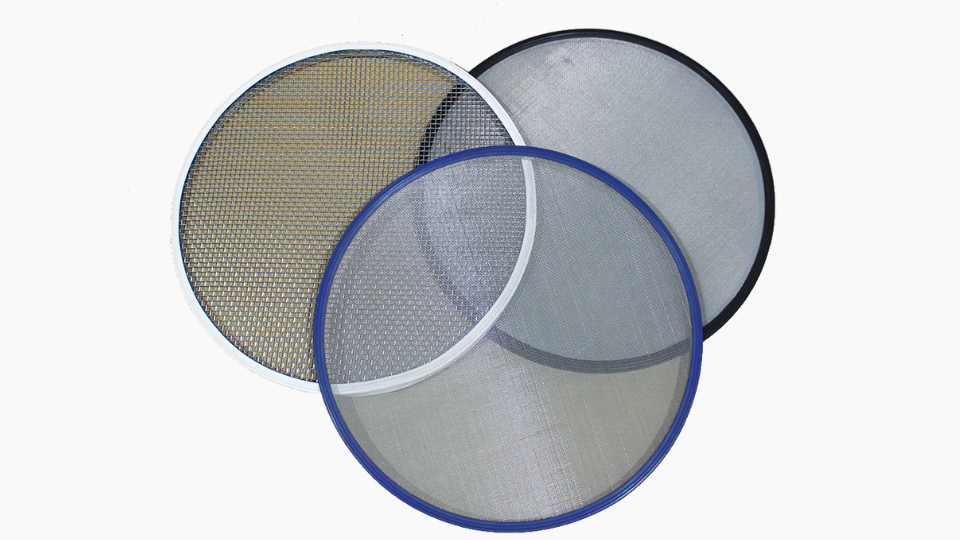

The Finex 22 is a well established solution for wet and dry applications. It can be used for safety sifting and accurate grading of your products.

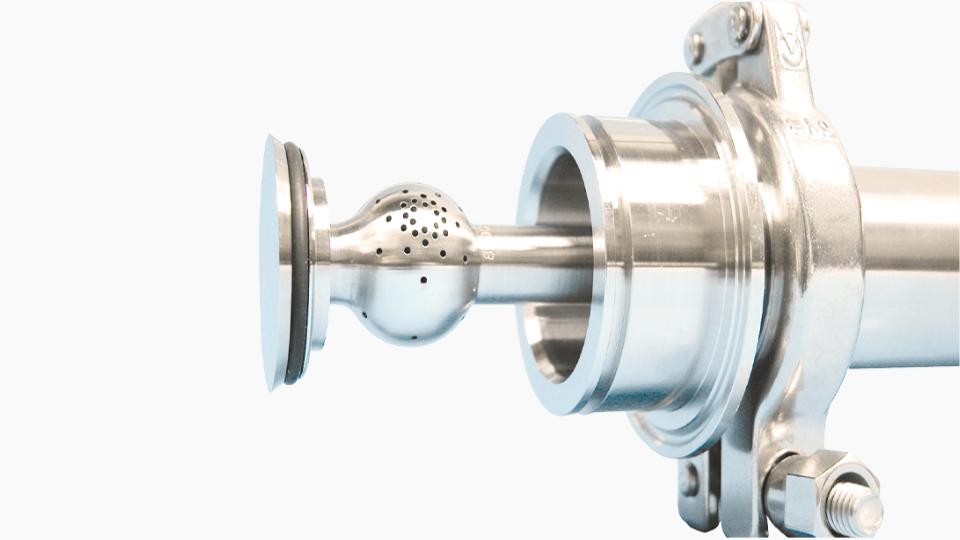

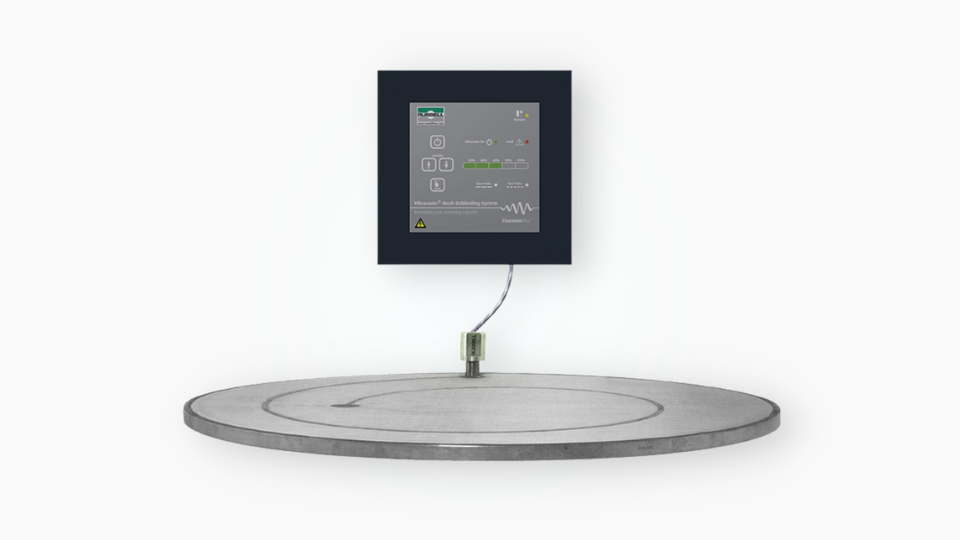

The drive system can be adjusted for full control over different materials, from typical powders to difficult viscous and thixotropic liquids. We offer a fully stainless-steel version of the unit, as well as a choice of optional inlets and outlets for your specific application needs.