Screening to improve your API quality

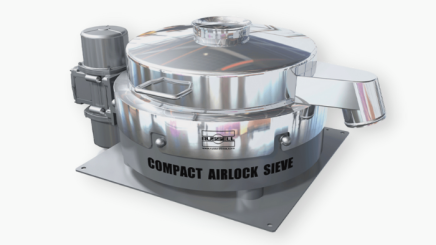

The Russell Compact Airlock Sieve™ is essential to ensure product quality and remove oversized contaminants from API’s, excipients and finished pharmaceutical powders. The sieve uses a pneumatic clamping system to provide a uniform and reliable seal to a validatable OEL 5 containment (less than 1µg/m3), protecting operators’ health and safety by minimizing exposure to dust. The cGMP design of the screener is based on clean lines, making sanitation easier and enhancing performance.